Glove Information

Glove Information

(1) Main Types of Examination / Disposable Glove

(a) Latex – manufactured from natural rubber latex (NRL) which is a milky fluid obtained from the Hevea Brasiliensis tree found mainly in South East Asia. Latex gloves provide the best barrier protection in areas of potential risk associated with blood-borne pathogens and other biohazards. The physical properties of the material combine excellent flexibility and uncompromised protection with a high degree of sensitivity. Latex outperforms other glove materials in terms of elasticity and tensile strength and provides excellent comfort and feel. Latex gloves are generally affordable and economical in terms of pricing.

The downside to latex is that as with many other natural products natural rubber latex contains proteins to which some individuals may develop an allergy. Around 1% - 6% of the general population and between 8% - 12% of regularly exposed healthcare workers are thought to be potentially sensitised to NRL although not all sensitised individuals develop symptoms.

Symptoms associated with latex allergy range from skin conditions such as dermatitis to in very extreme cases anaphylaxis which is potentially life threatening. NRL allergens attach to cornstarch which is used in the production of powdered gloves. This powder acts as a vehicle making the NRL proteins airborne when these gloves are used, enabling the allergens to be inhaled. This means that NRL allergic individuals may experience symptoms of an allergic reaction by being in a room where powdered NRL gloves are used even though they are not in contact with these gloves directly.

The UK Health and Safety Executive considers that natural rubber latex can be hazardous to health and employers should be aware of their legal obligations under the Health & Safety At Work Act 1974 and The Control Of Substances Hazardous To Health Regulations 2002. The UK Health and Safety Executive has the following policy statement on it’s website; “single use disposable natural rubber latex gloves may be used where a risk assessment has identified them as necessary. When they are used they must be low protein and powder free”. Please refer to www.hse.gov.uk/latex/law.htm for further information.

In many situations a risk assessment will suggest that in the presence of a risk of blood-borne pathogen transmission NRL is the safest choice of material providing the worker and patient are not sensitised to this. Not all NRL free gloves afford the same degree of protection against blood-borne pathogens so care must be taken in the choice of substitutes.

The UK Health and Safety Executive has published a useful leaflet titled ‘Latex and You’ and this is available to download in pdf format at www.hse.gov.uk/pubns/indg320.pdf.

We stock both powdered and powder free latex gloves and full details of the range can be found under the ‘Latex Gloves’ heading in the Products section.

(b) Vinyl– manufactured from Polyvinyl Chloride (PVC) Plastisol. Completely latex free and therefore ideal for users who are sensitive to natural rubber latex. Vinyl gloves have good resistance to oil and grease and are ideal for low risk applications. Vinyl provides a relaxed and comfortable fit that feels like a second skin. Vinyl gloves are generally very economical and affordable. We stock both powdered and powder free vinyl gloves and full details of the range can be found under the ‘Vinyl Gloves’ heading in the Products section.

(c) Nitrile – manufactured from Acrylonitrile-butadiene, a synthetic polymer. Completely latex free and therefore ideal for users who are sensitive to natural rubber latex. The soft formulation of nitrile provides excellent feel, comfort and flexibility to users and reduces hand fatigue. Nitrile has good resistance to oil, grease and a wide range of toxic chemicals and solvents. Nitrile gloves possess high abrasion and puncture resistance properties. We stock both powdered and powder free nitrile gloves and full details of the range can be found under the ‘Nitrile Gloves’ heading in the Products section.

(2) Glove Selection Guide

The following table should be used as a guide for users to choose the correct glove material depending on the purpose and application.

|

Properties |

Latex |

Nitrile |

Vinyl |

|

Barrier properties against viral transmission |

◊◊◊ |

◊◊ |

◊ |

|

Tear resistance |

◊◊ |

◊◊ |

◊ |

|

Puncture resistance |

◊ |

◊◊ |

◊ |

|

Tensile strength and elasticity |

◊◊◊ |

◊◊ |

◊ |

|

Protein content |

Present |

Not Present |

Not Present |

|

Comfort and finger dexterity to reduce hand fatigue |

◊◊◊ |

◊◊ |

◊ |

|

Tactile sensitivity for better feel |

◊◊◊ |

◊◊ |

◊ |

|

Resistance to oils and solvents |

◊ |

◊◊◊ |

◊◊ |

|

Resistance to chemicals |

◊ |

◊◊◊ |

◊ |

|

Food contact safety |

◊◊◊ |

◊◊◊ |

◊◊◊ |

|

Biodegradable and environmentally friendly |

◊◊◊ |

◊ |

◊ |

|

Price |

◊◊ |

◊ |

◊◊◊ |

|

|

|||

|

Indicator: Fair ◊ Good ◊◊ Excellent ◊◊◊ |

|||

Chemical Resistance

We are usually able to provide guidance in the selection of the most appropriate glove for use with specific chemicals and applications. The information is based on published research data and we strongly recommend that you use this guidance as part of a thorough COSHH risk assessment. Please contact us by email stating exactly what chemical you will be working with and we will rate the chemical resistance of each glove material from poor to excellent.

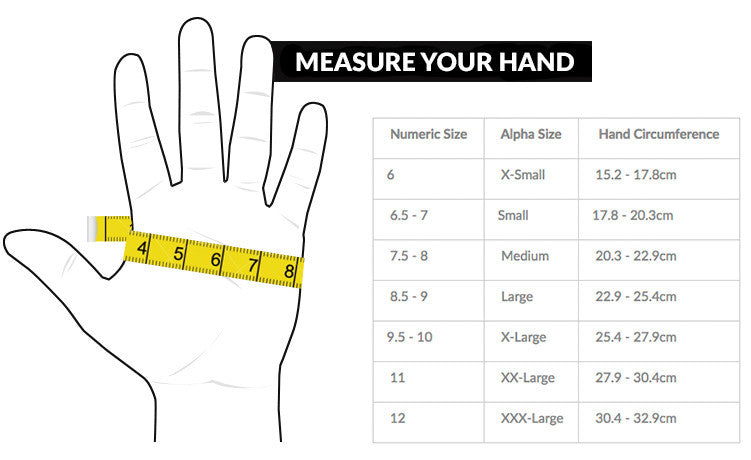

(3) Hand Size Guide

If gloves are too small they may be stretched, reducing protection and making them more likely to tear. If gloves are too large they can be pulled off by machinery or even pull the hand into moving machinery. Ill-fitting gloves will also greatly reduce dexterity and cause fatigue.

European Standard EN420 sets out general requirements for sizing.

To determine the size of glove required, measure the circumference of the dominant hand above the thumb and below the fingers, as shown in the diagram. This can then be referenced to the table below.

PLEASE NOTE

When a glove is indicated as being ‘One Size’ this is generally an 8.5 - 9 (Large)

(4) International Quality Standards

Gloves are regulated under two categories, medical and non-medical or ‘industrial’. The quality of a glove is measured by its ‘Acceptable Quality Level’ (AQL). This relates to the product’s freedom from pinholes and typically refers to the barrier protection confidence level. The lower the AQL, the better the quality of the glove. Manufacturers must evaluate the quality level of their gloves by testing each production batch. The inspection level is higher and stricter for medical gloves than industrial gloves. The AQL of a medical glove must be no more than 1.5.

When purchasing gloves for higher risk situations AQL should definitely be a factor in glove selection as it is a key indicator of the barrier protection of the product.

Statutory Regulation For Medical Gloves

All our medical gloves follow the compulsory European regulations.

Medical Devices Directive 93/42/EEC

This European directive details the minimum harmonised safety standards for medical devices. Compliance with the directive is indicated through the manufacturer displaying a CE pictogram on the product packaging. Only devices that meet the standards of the directive and have the CE mark can be sold in the European Union. CE marking is accredited after regular auditing processes.

Within the Medical Devices Directive there are different standards relating to the various devices. Regarding medical gloves the standard to follow is EN455 (medical gloves for single use) which is divided into three parts. All our medical gloves comply with EN455.

Statutory Regulation For Non-Medical Gloves

Our non-medical or ‘industrial’ gloves are used for non-medical purposes and are either AQL 1.5 or AQL 4.0. They follow the compulsory European regulations.

Personal Protective Equipment: PPE Directive 89/686/EEC

This European directive details the minimum harmonised safety standards for personal protective equipment. Compliance with the directive is indicated through the manufacturer displaying a CE pictogram on the product packaging. The PPE directive covers a wide range of head to foot personal protective equipment (disposable and non-disposable). In respect of disposable items gloves are deemed to be protective workwear. All our non-medical gloves comply with the PPE directive.

EN420: General Requirements For Protective Gloves

This standard defines the general requirements for glove design and construction, innocuousness, comfort and efficiency, marking and information applicable to all protective gloves.